Designing a product enables you with 2 Options, 2D CAD and 3D CAD, the difference is huge when compared 2D to 3D. here are the differences between the both.

Mega structures to Marvelous Engineering all begin from a stroke of pencil on paper. Designers or Artists Decades ago followed design process which involved pencil and paper. This evergreen process is still followed till date however with the advent of 2D CAD (Computer Aided Designing), the design process revolutionized across the globe. The use of 2D CAD in design process enabled manufacturers and engineers to design products and component like never before. Certainly, 2D CAD had its limitation which restricted designers and engineers from utilizing their maximum potential. The Limitations amongst the Designers and Engineers in terms of product designing gave rise to 3D CAD. Mechanical designs are created using 3D CAD which results to be much efficient and accurate in comparison to 2D CAD

Majority of the industries are shifting towards 3D CAD solution for enhanced designs and products and to stay up in the competition. 3D CAD gives a leverage when it comes to designing and product manufacturing. How exactly does 3D CAD leverage your design and Manufacturing Process.

DIFFERENCE BETWEEN 3D CAD and 2D CAD

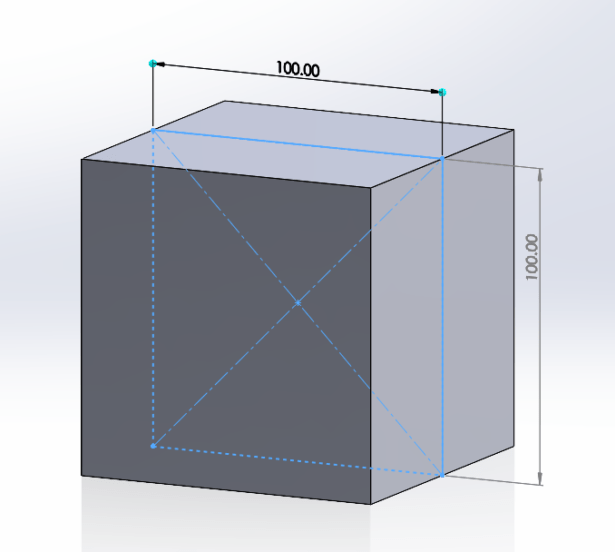

1. GEOMETRY

2D CAD enables designers to use shapes such as rectangle, circle and triangle which requires one point of reference. However, with the use of 3D CAD, designers are provided with the ability to utilized enhanced and advanced shapes such as polygon, rhombus, Cube, etc. which requires more than one point of reference. This basic addon enables the designers to create designs with much more accuracy similar to the 3D Product.

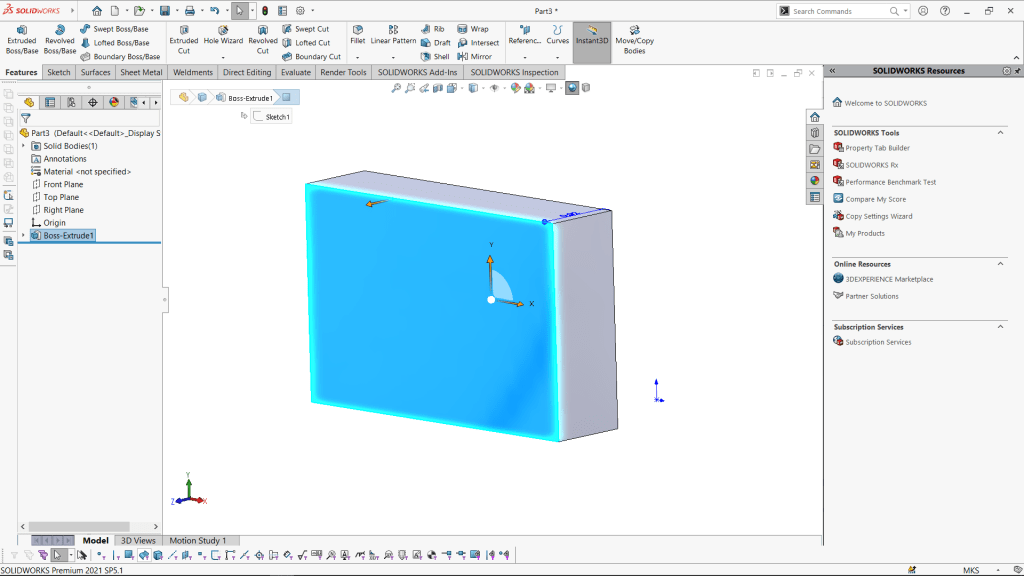

2. QUICK DESIGN CHANGES

Designing is 2D happens to be time consuming and if encountered an error and potentially required a rework, the time consumed to do the necessary changes could be arduous. Whereas, when working with 3D CAD, Designing and design changes could be done much faster and accurately in comparison to 2D CAD designing. 3D CAD enables you to alter product without worrying about the sketch at the core and this process enables the designers to perform changes to the design without an induction of error.

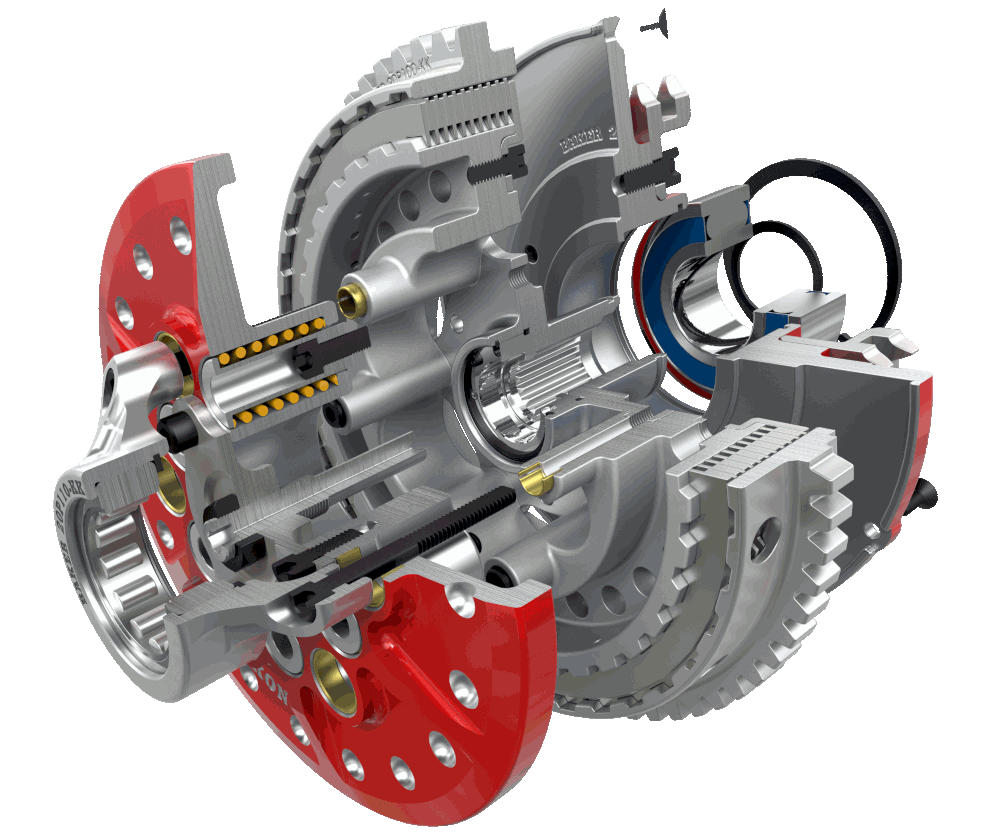

3. VISUALISATION

In comparison to 2D Drawings, 3D Designs enables the user/ consumer to visualize the design in three-dimensional space. This feature provides the viewer with ample view of the product and provides deep understandings. The visualization in multi-dimensional spaces provides the opportunity to resolve or predict locations for possible error upon manufacturing.

4. EASIER CHECKING PROCESS

Products manufactured using 2D Designs tend to carry more errors when compared to 3D Design. The reason happens to be the complexity of design, where the 2D CAD Design falls short to simply and highlight the potential area of errors. The use of 3D Designs eliminated the crucial error as the designs are in multi-dimension which ultimately simplifies the complexity of the design.

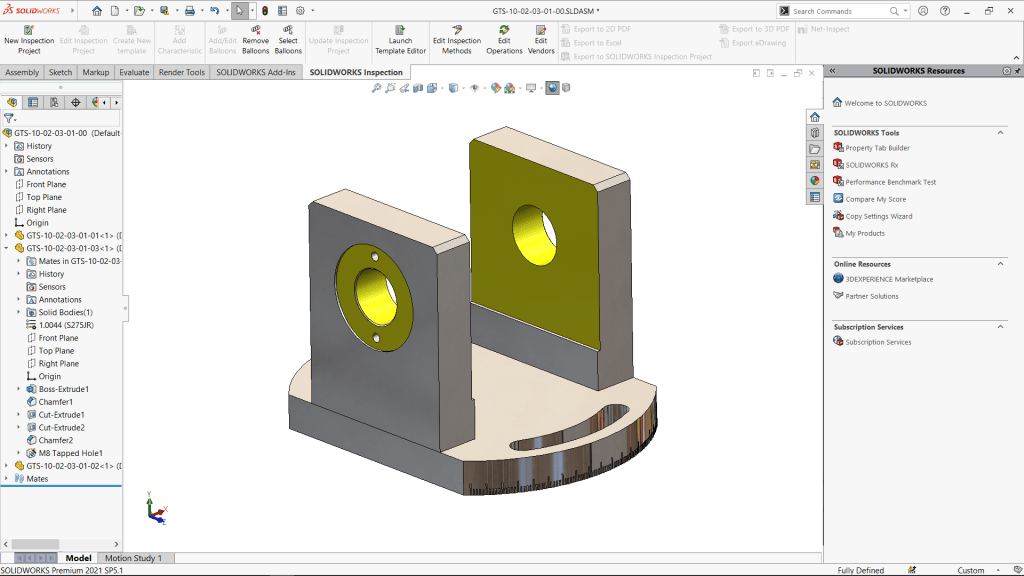

5. OPTIMIZE DESIGNS

The use of 3D CAD designing enables one to optimize the product for better performance prior to the prototype/ production stages, whereas a prototype is compulsory for optimization when used 2D CAD.

LOOKING FOR 3D CAD SOLUTION?

Panshul Technologies LLP, offers 3D CAD solution across various industries verticals and domains. If you contain plan to introduce 3D Solutions in your industry, Panshul Technologies LLP will be the perfect guide for you.